How Does A Shrimp Peeling Machine Work?

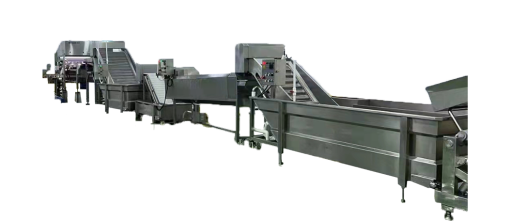

In the seafood processing industry, efficiency and quality are paramount. One of the most significant innovations in this field is the shrimp peeling machine. This machine automates the peeling process, drastically reducing labor costs and improving product quality. This article will explore the workings of shrimp peeling machines, their advantages, and their impact on the seafood industry.

The Need for Automation in Shrimp Processing

The demand for shrimp has surged globally, leading to increased pressure on processors to deliver high-quality products quickly. Traditionally, shrimp peeling was a labor-intensive task requiring skilled workers. The process involved manually removing the shell from each shrimp, which was time-consuming and often resulted in inconsistent quality. However, as the industry evolved, so did the technology. The introduction of shrimp peeling machines has transformed how shrimp are processed, allowing for greater efficiency and consistency.

Historical Background of Shrimp Peeling Machines

The first automatic shrimp peeling machine was invented by James Martial Lapeyre in 1949. This groundbreaking invention allowed processors to peel approximately 1,000 pounds of shrimp per hour, a task that would typically require up to 150 workers if done manually. The success of this machine laid the foundation for modern shrimp processing technology. Over the years, advancements in engineering and design have led to more efficient and versatile machines that can handle various shrimp sizes and types.

Types of Shrimp Peeling Machines

There are various types of shrimp peeling machines available today, each designed to meet specific operational needs:

Automatic Shrimp Peeling Machines: These machines can handle large volumes and operate continuously, making them ideal for large-scale processors. They often come equipped with advanced features such as automated sorting and quality control systems.

Compact Shrimp Peeling Machines: Suitable for smaller operations or restaurants, these machines occupy less space while still providing efficient peeling capabilities. They are designed for ease of use and maintenance.

Customizable Systems: Many manufacturers offer customizable solutions tailored to specific shrimp sizes and peeling styles. This flexibility allows businesses to adapt their equipment to meet changing market demands.

How a Shrimp Peeling Machine Works

The operation of a shrimp peeling machine can be broken down into several key stages:

1. Loading the Shrimp

Shrimp are either manually placed into trays or fed automatically into the machine. Some systems include a pre-cleaning stage where contaminants are removed before peeling begins. This initial step is crucial for ensuring that only high-quality shrimp are processed.

2. Gripping Mechanism

Once inside the machine, clamps or rollers grip each shrimp individually. This mechanism ensures that only the shell is gripped firmly while minimizing damage to the meat. The design is engineered to apply just enough pressure to hold the shrimp securely without crushing it.

3. Peeling Process

The actual peeling process involves several steps:

Shell Separation: Rubber rollers apply friction to separate the shell from the meat effectively. The design ensures that more meat is recovered compared to manual peeling methods.

Cutting Mechanism: Blades cut through specific sections of the shell without damaging the meat, allowing for various peeling styles such as tail-on or completely peeled. This versatility is essential for meeting different market preferences.

Deveining: After shell separation, brushes or forks may be used to remove any remaining veins from the shrimp meat. This step is important for ensuring product cleanliness and quality.

4. Sorting and Discharge

Once peeled, shrimp are sorted and discharged onto an inspection conveyor for quality checks before packaging. The shells are collected separately for disposal, often being processed for use in other products like seafood stock or animal feed.

Advantages of Using a Shrimp Peeling Machine

The benefits of employing a shrimp peeling machine include:

Increased Efficiency: These machines can peel thousands of shrimp per hour, significantly reducing processing time compared to manual methods. This efficiency allows processors to meet high demand without sacrificing quality.

Cost Savings: By minimizing labor costs and maximizing yield (up to 10% more meat recovered), processors can achieve substantial savings over time. The initial investment in machinery is often offset by these long-term savings.

Consistency and Quality: Automated systems provide uniformity in size and quality that is difficult to achieve through hand peeling. This consistency is crucial for maintaining customer satisfaction and meeting regulatory standards.

Hygiene and Safety: Modern machines are designed with food safety in mind, often featuring stainless steel construction that meets hygiene standards. This design minimizes contamination risks during processing.

Why Choose Soontrue for Your Shrimp Processing Needs

In today's food processing industry, choosing a reliable equipment manufacturer is crucial. Soontrue is a professional packaging manufacturer that offers a variety of product packaging machines, including efficient shrimp peeling machines. Our equipment not only enhances production efficiency but also ensures product quality to meet market demands for high-quality seafood.

Soontrue is committed to providing customized solutions tailored to different production needs. By choosing Soontrue, you will receive advanced technical support and exceptional customer service to help your business stand out in a competitive market.

Conclusion

Shrimp peeling machines have transformed seafood processing by automating what was once a labor-intensive task. Their efficiency, cost-effectiveness, and ability to maintain high product quality make them indispensable in modern shrimp processing facilities. As technology evolves, we can expect further innovations that will enhance productivity and sustainability in this vital industry. The ongoing development of these machines will benefit processors and consumers seeking high-quality seafood products at competitive prices. Integrating advanced machinery like those offered by Soontrue ensures that businesses remain competitive while meeting consumer demand for quality seafood products efficiently and sustainably.