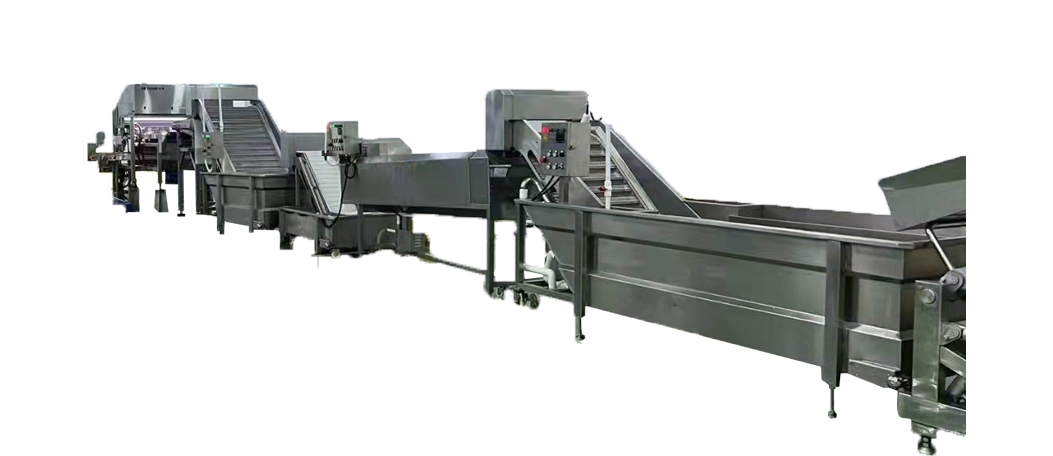

SDL100A Automatic Shrimp Deheading Processing Line

The SDL100A Automatic Shrimp Deheading Processing Line is a highly efficient solution designed for modern commercial shrimp processing. It automates the complete deheading shrimp workflow—from feeding to sorting—helping processors significantly reduce labor costs while ensuring consistent and stable product quality. As a reliable piece of shrimp processing equipment, this system is ideal for seafood factories aiming to upgrade their production capacity with dependable, high-performance shrimp processing machines.

Key Features

Integrated Six-Part Processing Line

The SDL100A consists of a pouring device, elevators, a shrimp deheading machine, washing elevator, sorting device, and collecting unit—combining into a smooth, fully automated shrimp processing line.

High-Quality Deheading Performance

Precise, stable deheading ensures minimal product damage and uniform processing results, making it suitable for various commercial applications.

Labor Saving & Efficiency Boost

Automation replaces repetitive manual work, reducing labor costs and improving processing consistency across the entire shrimp processing machine workflow.

Easy Cleaning & Maintenance

The independent electric box design and water-washable mechanical components make daily cleaning simple and convenient—ideal for strict hygiene environments.

Flexible to Production Needs

The line can be paired with customized feeding systems, conveyors, and layouts to accommodate different plant sizes and processing capacities.

FAQ

Q1: How many people are needed to operate the machine?

A: Typically, one operator is enough to feed shrimp into the machine.

Q2: Can the machine handle different shrimp sizes?

A: Yes. It performs best with sizes 21/25 to 61/70. For smaller shrimp such as 71/90, the efficiency of peeling and deheading may be lower.

Q3: Is it convenient to change the shrimp specification?

A: Yes. The servo-driven system simplifies adjustments, and multiple formulas can be saved on the HMI for quick switching.

Q4: Can you provide an automatic feeding system for multiple shrimp lines?

A: Yes. We can customize a full feeding and conveying system based on your factory layout and production capacity.

Q5: Is daily maintenance convenient?

A: Yes. The mechanical parts and conveyor belts can be washed directly with water, making daily maintenance easy and efficient.

| Model | SLD100A |

| Peeling range | From 41/50 to 110/120 pcs per pound |

| Shrimp peeling speed | About 1000 kg/hour. Equals to 30-40 labors |

| Water consumption | About 750 L/h |

| Rated power | 13.5KW |

| Power supply | AC 220v/1ph/50Hz |

| Machine weight | About 2500kg |

| Shrimp Damage Ratio | About 2% |