ZL180-PX Multihead Vertical Packing Machine

Application:

Mainly used for packing granules, strips, slice, lumps, powder with different packing types.

Packing Exambers:

Vertical Packaging Machine: Optional accessories

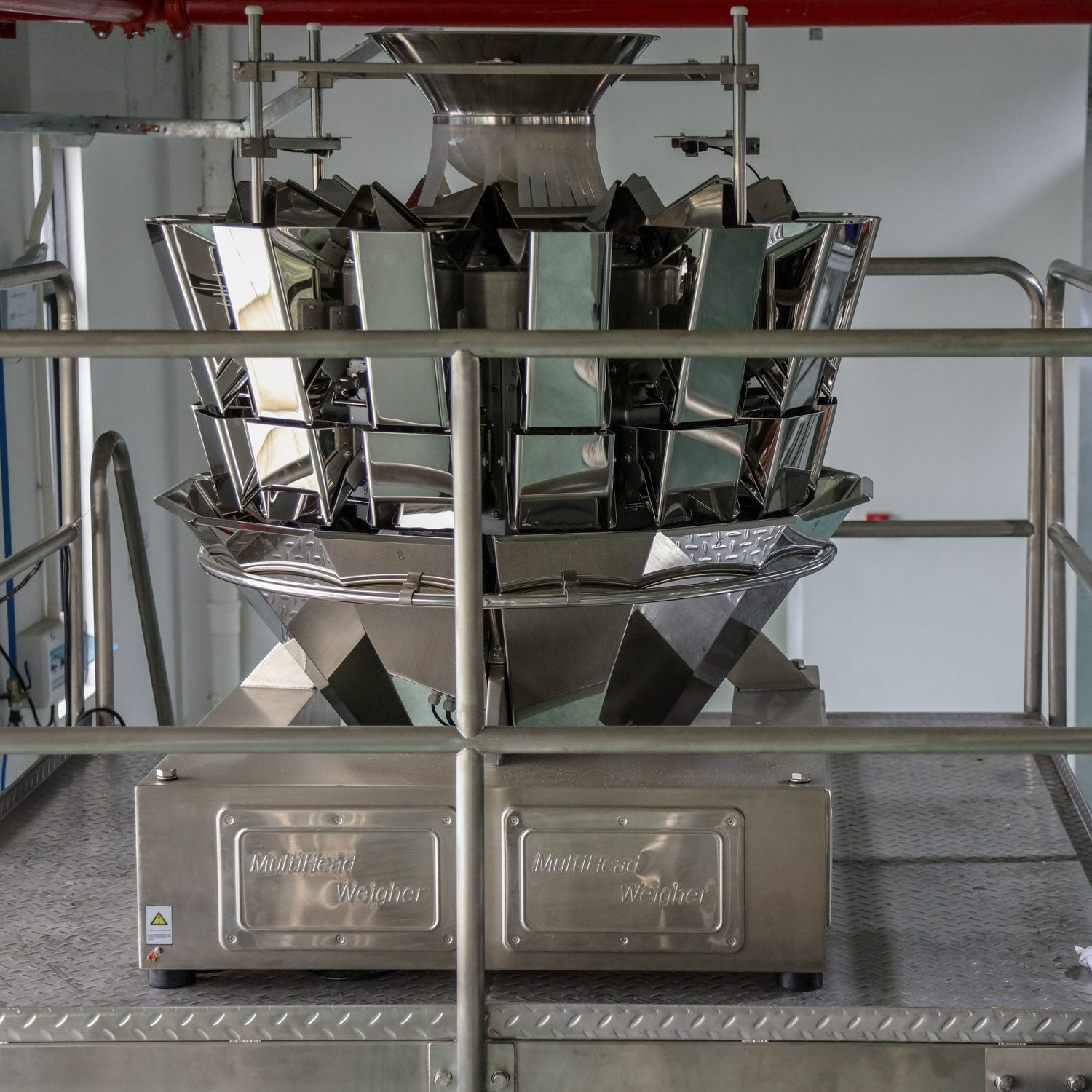

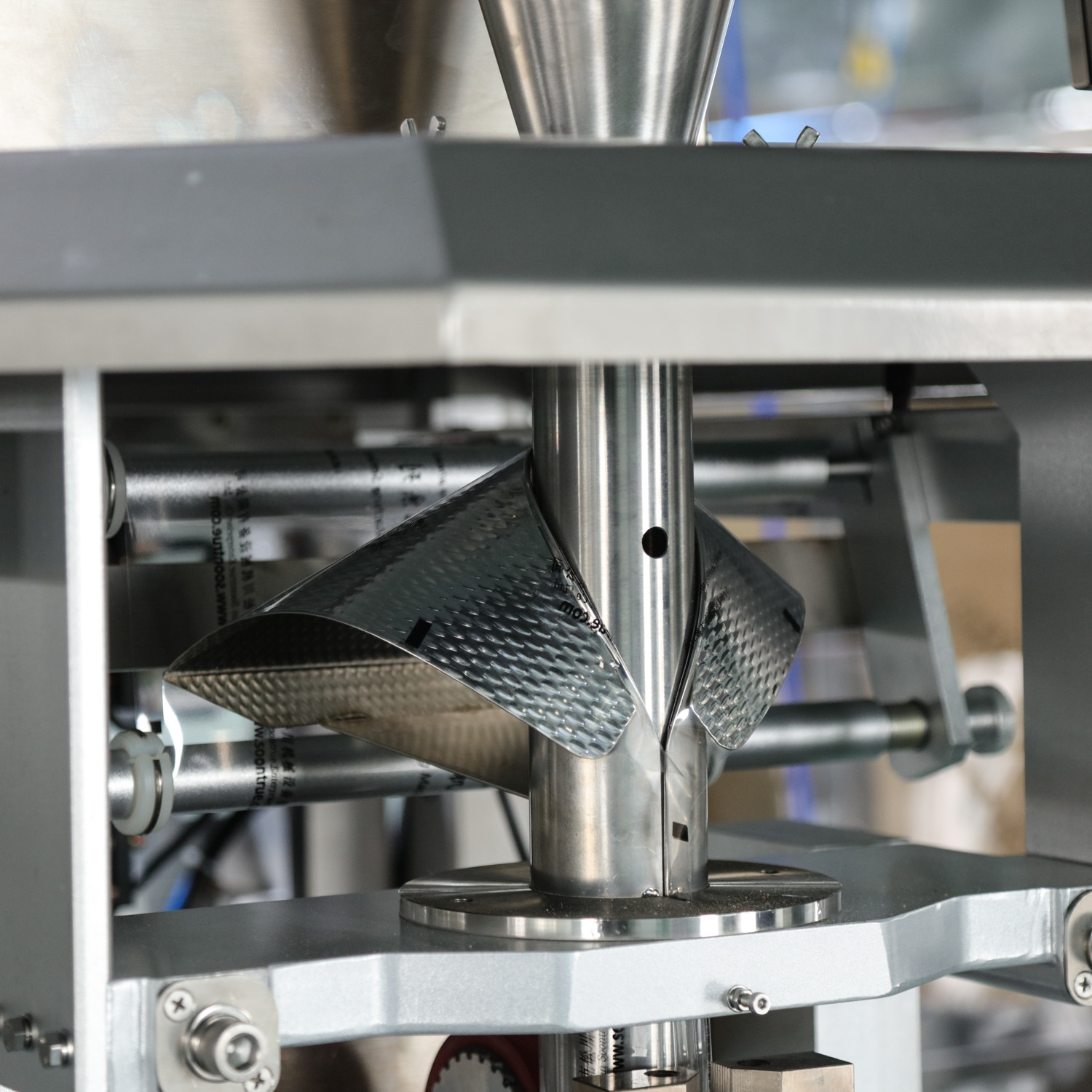

1.multi-head weigher

● Features

- One of the most economic&stable multi-head weigher in the world the best cost-effective

- Stagger Dump avoid bigger items pile up

- Individual feeder control

- User friendly touch screen equipped with multiple language

- Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

- 99 preset program for multiple tasks.

2.Z-TYPE CONVEYOR

- Features

The conveyor is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

3.SUPPORTING PLATFORM

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

4.OUTPUT CONVEYOR

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

Features

Optimized design for easier operation and higher efficiency.

Compact structure ensures stable performance.

High-speed packing with specially designed key components.

Advanced servo control system for precise adjustment and flexible packaging of different products.

Multiple bag styles available: pillow type, hole punching bag, conjoint bag, and hole punching with conjoint bag.

Flexible weighing options: multi-head weigher, auger, electric scale, volume cup, etc.

Applications

The ZL180-PX Vertical Packaging Machine is ideal for packing a wide range of materials, including:

Food products: candy, sunflower seeds, peanuts, nuts, beans, potato chips, popcorn, almonds, biscuits, chocolate, dry fruit, jelly.

Vegetables & frozen food: shredded lettuce, cabbage, romaine, spring onion, leek, frozen vegetables.

Pet food & snacks.

Hardware and plastic items.

This machine is suitable for granular, strip, sheet, irregular, or lightweight products, making it highly versatile for different industries.

Reminder: Our experienced R&D team can provide customized packaging solutions based on your product characteristics and production requirements.

FAQ – Vertical Packaging Machine

Q1: How should I choose the right VFFS packing machine?

A: We recommend the suitable model based on your product type, package size, and bag style. For example, volumetric cup filler or multi-head weigher for granular materials; auger scale for powder; liquid pump for liquid products.

Q2: I'm worried I don't know how to operate the machine.

A: No need to worry. Our machine uses a servo control system with an easy-to-use HMI. Most operations are completed with simple start/stop buttons. We also provide instructional videos and the HMI supports memory function for quick setting recall.

Q3: What technical support can I get after purchase?

A: We offer 24/7 online technical support, installation and maintenance videos, and on-site installation services for large projects (buyer covers related costs).

Q4: How do we build trust in the first cooperation?

A: We ensure transparency by providing factory video tours, detailed explanations, and acceptance tests before shipment. You can also see similar case studies and references.

Q5: How can I get a custom packing machine? A: Share your product samples, packaging requirements, and film type with us. With 30 years of experience, we will design the most cost-effective and suitable solution for your needs.

What is a Vertical Packaging Machine?

A vertical packaging machine (VFFS) is an automated packing system that forms, fills, and seals bags in a vertical process. It is widely used in food, pharmaceuticals, cosmetics, and daily consumer goods. The ZL180-PX offers space-saving design, high precision, and reliable sealing for various materials like plastic films, laminates, and paper.

Key Highlights

Vertical Form-Fill-Seal Technology: Airtight and secure packaging.

Versatile Packaging Styles: Adapts to multiple bag designs.

User-Friendly HMI: Simple adjustments and monitoring.

High-Speed Performance: 20–100 bags per minute.

Durable & Long Service Life: 10–15 years with proper maintenance.

Flexible Pack Size: Handles bags 50–180mm long and 50–150mm wide.

The ZL180-PX Multihead Vertical Packaging Machine is the perfect solution for companies looking to improve packaging efficiency, reduce labor, and ensure consistent product quality.

Multihead Vertical Packaging Machine: Technical Parameters

| Model | ZL-180W | ZL-180H | ZL-200W | ZL-200H |

| Bagging size range | L50-190mm W50-150mm |

L50-190mm W50-150mm |

L50-300mm W90-200mm |

L50-275mm W90-200mm |

| Packing speed | 20-90 bags/min. | 20-140 bags/min | 20-90 bags/min | 20-120 bags/min |

| Packing film width | 100-320mm | 100-320mm | 200-420mm | 200-420mm |

| Packing material | PP, PE, PVC, PS, EVA PET, PVDC PVC, OPP/CPP etc. | |||

| Air consumption | 6kg/cm² 80L/min. | |||

| General power | 3.9 kw | 4.65 kw | 3.85 kw | 4.9 kw |

| Power supply type | 1Ph. 220V 50Hz | |||

| Machine weight | 210Kg | 240Kg | 240Kg | 280Kg |

| Machine dimensions | 1500x960x1120mm | 1500x960x1220mm | 1650x1030x1270mm | 1650x1030x1420mm |