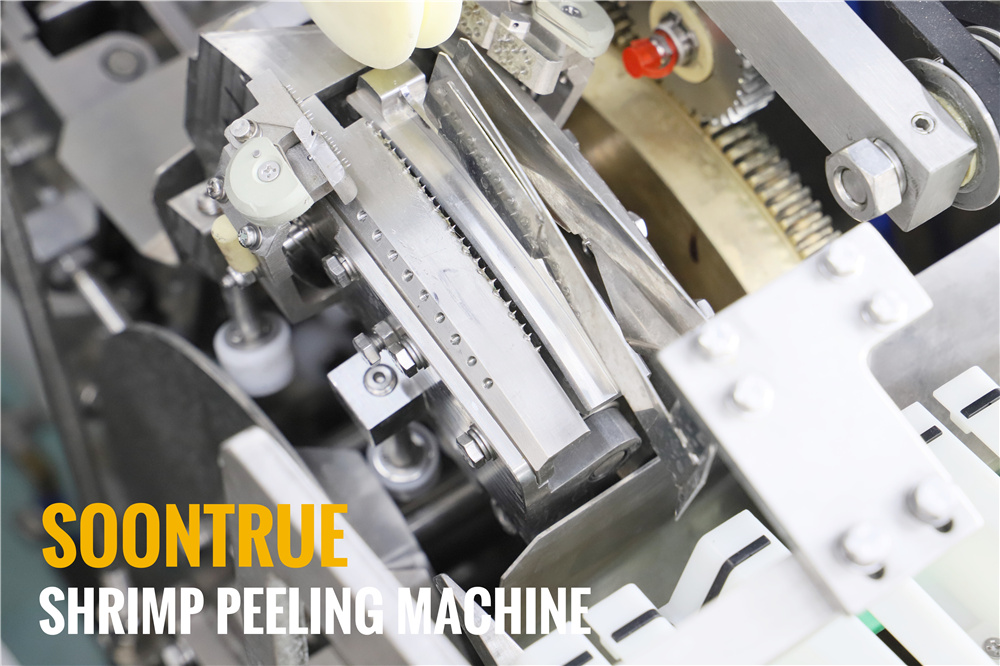

Automatic Shrimp Peeling Line

The Automatic Shrimp Peeling Line is designed to efficiently process shrimp peeling and deveining with minimal labor input. By integrating advanced automation, it ensures consistent product quality while significantly reducing labor and training costs. Compact in size, easy to operate, and simple to maintain, this machine is widely used in aquaculture plants and aquatic product processing industries worldwide.

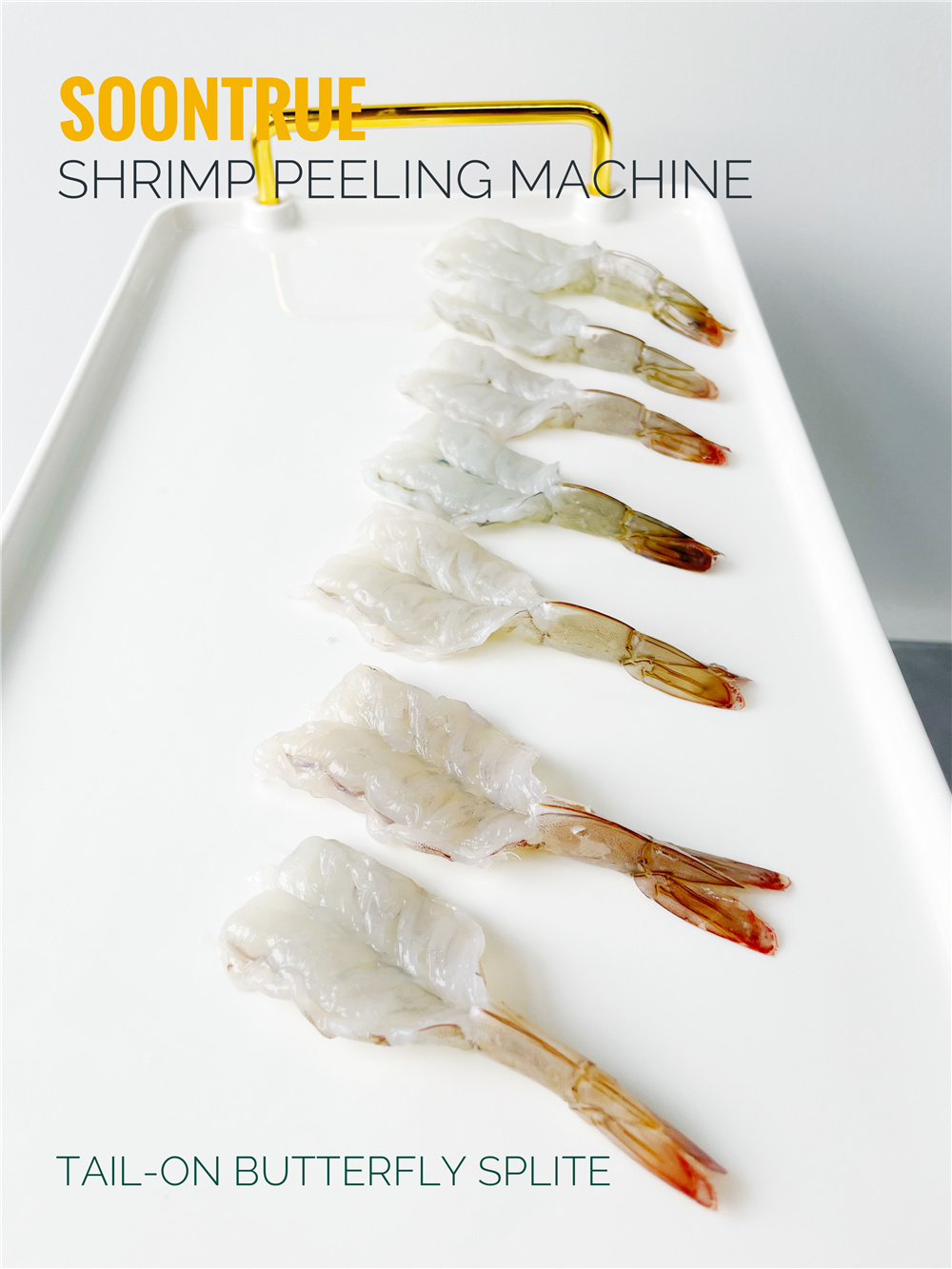

It is suitable for handling shrimps of different sizes (21/25 to 61/70), with options for various processing styles such as EZ peel and multiple types of PTO (Peeled Tail-On).

Key Features

Automatic peeling & deveining – Streamlines shrimp processing with precision.

Wide size adaptability – Processes shrimp from 21/25 up to 61/70 count.

Flexible specifications – Supports EZ peel and multiple PTO styles.

Labor-saving design – Only one operator needed per machine.

User-friendly operation – Servo drive system with HMI interface allows quick changeover and recipe storage.

Stable quality – Ensures consistent peeling performance across batches.

Compact footprint – Saves valuable factory space.

Easy cleaning & maintenance – Independent electric box, washable mechanical parts, and conveyor belt.

Applications

- Shrimp aquaculture farms

- Seafood processing plants

- Frozen seafood production lines

- Export-oriented shrimp processors

This machine helps businesses increase productivity, reduce manual labor costs, and maintain uniform quality standards in large-scale shrimp processing.

Frequently Asked Questions (FAQ)

Q1: How many people are required to operate the machine?

A1: Typically, only one operator is needed to feed shrimp into the machine.

Q2: Can the machine handle different shrimp sizes?

A2: Yes. It works best with shrimp sizes from 21/25 to 61/70. For smaller shrimp (71/90), peeling and deveining efficiency may be lower.

Q3: Is it easy to change shrimp specifications?

A3: Absolutely. The servo drive system simplifies adjustment, and settings can be saved through the HMI for fast recall. Compared to other machines, ours offers faster and easier commissioning, giving you greater flexibility.

Q4: Can the machine be integrated with an automatic feeding system?

A4: Yes. We can provide customized solutions based on your factory layout and production capacity. The system can include working platforms, in-feed conveyors, and out-feed conveyors.

Q5: Is daily maintenance simple?

A5: Yes. Thanks to its independent electric box and water-washable components, the machine is designed for quick cleaning and hassle-free maintenance.

Why Choose Our Shrimp Peeling Line?

By combining automation, versatility, and reliability, the Automatic Shrimp Peeling Line delivers superior performance in modern seafood processing. Whether you need a single unit or a fully automated line with conveyors, it helps your factory achieve higher efficiency, reduced costs, and consistent shrimp quality.

| Model | HB-320 |

| Shrimp peeling specification range | 21/25-61/70 |

| Max. capacity | 70pcs shrimp/min. |

| Water consumption | 120 L/h |

| Water pressure | 0.4 MPa |

| General power | 1.5 kw |

| Power supply type | AC220V 50Hz |

| Machine weight | 230 Kg |

| Machine dimensions | 930 x 1040 x 1300mm |

Splitting & Peeling style:

| Headless shrimp | E-Z Peeling Style | Tail- On 2 to 5 | Tail- On Deep Cut | |

| Tail-On Butterfly Split | Tail- On Gradual Cut | Tail- Off Completely Peel | ||

| Headed shrimp | Shell Split 1-6 | Tail- On Completely Split | ||