big pillow bag flow wrapping machine - SZ502

Application:

Mainly used for packing various regular and solid products such as multi-pcs face masks, cake, bread, biscuit, instant noodle, chocolate, daily necessities, medicine, hardware or any product in tray.

Introduction

Parameter

Introduction:

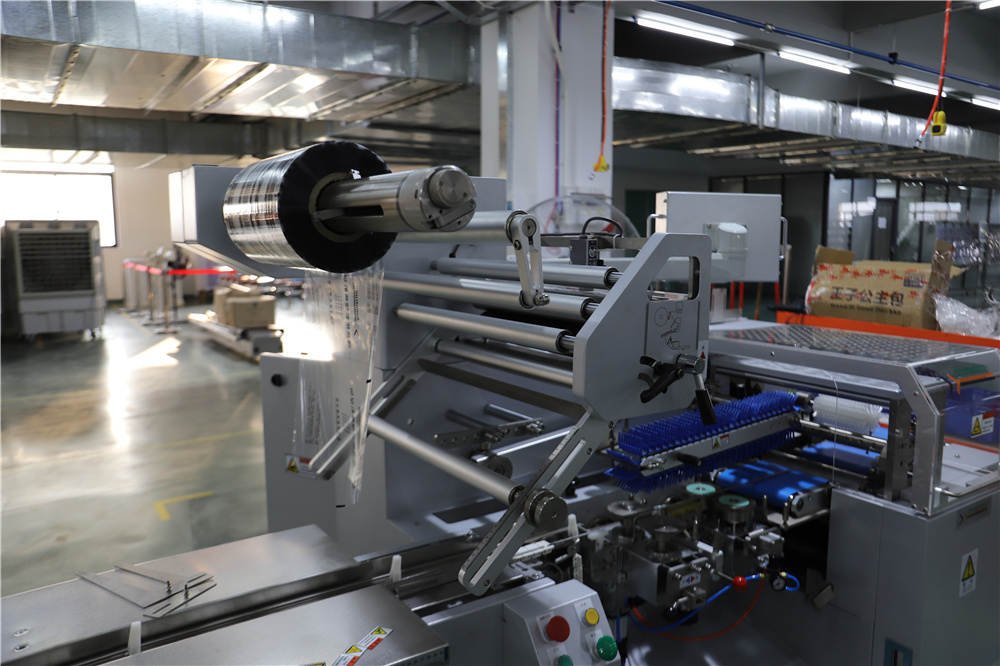

SZ502 horizontal flow wrap machine is ideal for suppliers of products that must be packaged individually. Flow wrapping is a horizontal packaging process in which product enters the machinery and is wrapped in clear or printed film. The result is a tightly fitted flexible package with a horizontal back seal and end seal.

Horizontal Full Servo-control Packaging Machine Features

Simple system structure: System is composed by servo motors, servo driver and touch screen. Servo driver is built-in motion control formula of packaging machine without any independent controller, all wiring is connector assembly. Performance of compact design, convenient maintaining and competitive price.

Simple operation: With intelligent control system of HMI, it gets simple parameters setting and adjustment.

Big bagging size range: Bag length can be set between a wide range via color mark tracking or bag length presetting. To set bag length is much easier and flexible.

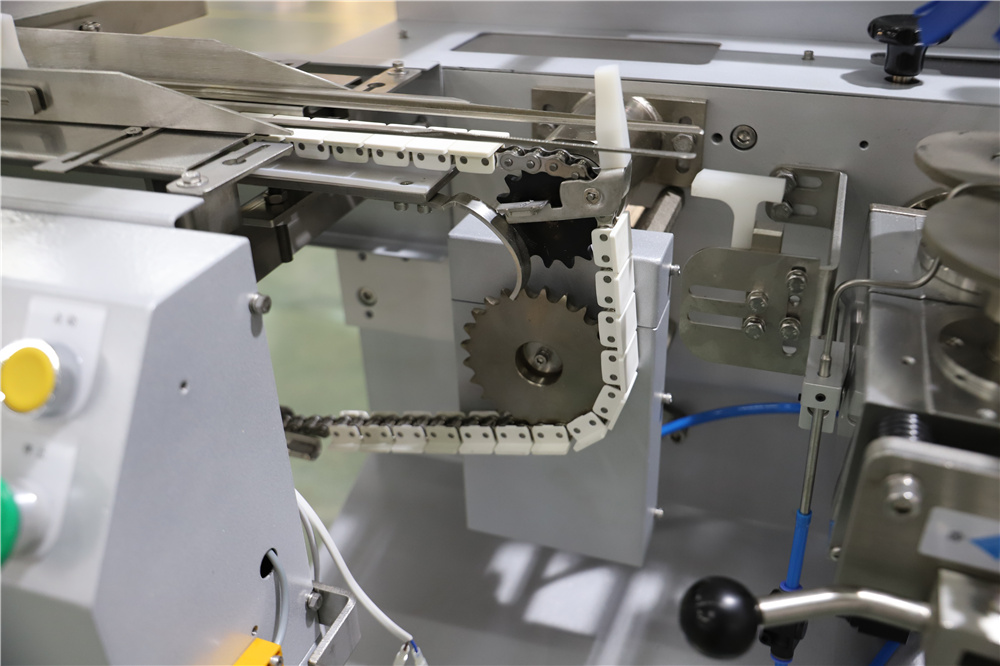

Shaftless driving: Adopt shaftless driving technology, no mechanical joint, each shaft is controlled by servo motor with gear reducer.

Auto-shift cutter: Cutter is running with variable shift, speed curve is generated automatically without manual adjustment, and save mechanical cams.

Faster line speed: Max. line speed is up to 50m/min., long package can be packed faster.

Faster packing speed: With color mark tracking function, max. packing speed can be up to 200bags/min(Double jaws).

High accuracy of color mark tracking: Color mark tracking accuracy is up to 0.1mm

Packless function: With this function, no matter in-feed products are continuous or intermittent, each package will be fed with product inside and no empty bag, so as to reduce loss of film material.

Cutless function: With this function, if sensor detects any product is out of position inside film, cutter will stop and restart until this product is discharged.

Film splicer: Finished film roll will be spliced new film roll automatically by film splicer without machine stop, so as to save operation time and labor.

Cutter torque protection: System detects stress condition of cutter automatically. When hard product is being cutted, resistance is bigger than preset value of torque protection, cutter will stop immediately and run backward, machine can be restarted until this cutting product is discharged without restoration. Value of torque protection is set via touch screen.

Customizable special function: Machine can be modified according to customer’s requirement. The whole machine is applied with multiple safety protection devices, which can be equipped with various automatic feeding system.

SZ502 Machine Standard features

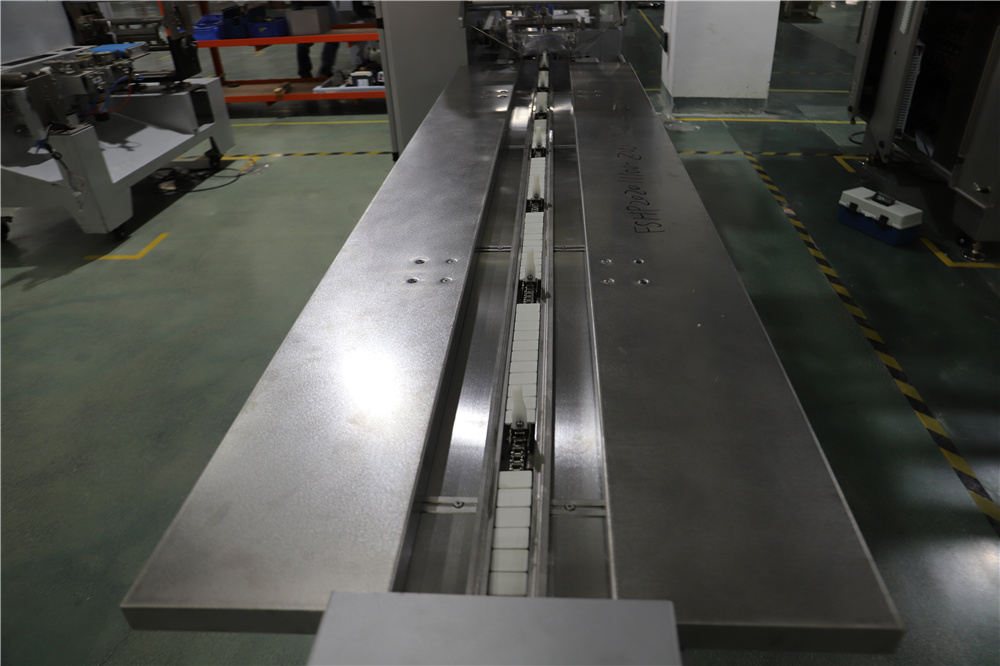

1. Sanitary machine design allows for easy clean-up

2. Compact machine body for smaller footprint

3. Intelligent control system with servo motors

4. Color mark tracking

5. Machine can easily be integrated with Soontrue’s full line of automatic feeding system and other upstream or downstream equipment

Maintenance and inspection

1.Maintenance and clean for machine every day or every shift.

(1) Clean the machine each time after packaging.

(2) Turn off the power before cleaning the machine to make the temperature of heating part decrease.

(3) Never spray water or steam directly on the machine when cleaning.

(4) Main components to be cleaned:

(1) Clean the machine each time after packaging.

(2) Turn off the power before cleaning the machine to make the temperature of heating part decrease.

(3) Never spray water or steam directly on the machine when cleaning.

(4) Main components to be cleaned:

* Remove the little pieces of material stay on the in-feed conveyor by compressed air or in other way.

* Brush off the film pieces adhered to the cutter surface by wire brush applied with the silicone oil.

* Clear the dirt on the control panel, safety cover and operating surface by a piece of soft cloth.

* Conductive ring of the mid sealing tool and end sealers: clean it once a week or two weeks. Clean the conductive ring by the back of the sandpaper when power off.

* Brush off the film pieces adhered to the cutter surface by wire brush applied with the silicone oil.

* Clear the dirt on the control panel, safety cover and operating surface by a piece of soft cloth.

* Conductive ring of the mid sealing tool and end sealers: clean it once a week or two weeks. Clean the conductive ring by the back of the sandpaper when power off.

2.Maintenance and clean for machine every month.

(1) Apply the lubricating grease on the bearing of the end sealers.

(2) Apply the lubricating grease on the gear and chain (pulley) of the driving unit.

(3) Check the tightness of the chain and belt of the driving unit, and tighten the loosed one.

(4) Check the tightness of the fastening screw or nut of all parts, and tighten the loosed one.

3.Relevant inspection for machine once a half year.

(1) Check the wear intensity of the belt of the driving unit, and replace the worn-out one.

(2) Check the wear intensity of the rubber roller, and replace the one affecting the film advancing effect.

(3) Properly adjust the brake unit of the film-carrying roller.

(4) Check all wearing parts, and immediately replace the damaged one.

(5) Check the fastness of the wiring on the electrical terminal plate, and tighten the loosed one. Check the inverter, programmable controller and circuit board, and remove the dust or dirt on them by the compressed air.

FAQ

Q1: What type of machine for food packaging do you have

Answer: We will recommend suitable models based on your product characteristics, size, and type of placement, such as model with top film loader, bottom film loader, rotary end sealing, box motion end sealing, etc. In addition, different types of in-feed conveyors can also meet different types of products feeding methods, such as chain type, belt type, feeding-on-film type, etc

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our machine for packaging is servo controlled, which greatly simplifies the difficulty of operation and commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. If you have different products or packages that need to be changed, we can provide instructional videos to give you step-by-step tutorial. Also, the HMI has memory function, which is convenient for you to reload the settings in the future.

Q3: If I buy your automatic packaging machine, what technical support can I get?

Answer: Whether buying a customized packaging machine or an automatic packaging system, we will provide you with 24-hour online technical support. In addition, we can also provide you with instructional videos on the installation and daily commissioning and maintenance. For some custom-made automatic packing system, our professional after-sales technicians can also provide on-site installation and commissioning services as per request (buyer should bear the cost for the service).

Q4: How do we build trust in the first business?

Answer: We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the high quality packaging machine you need is ready before shipment.

Q5: How can I find the custom packaging machine I need?

Answer: We will fully communicate of the information of your products, packaging scheme, and feeding method. We have nearly 30 years of experience as an packaging machine factory and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of products and packaging films for testing, in order to find the most suitable and cost-effective solution for you.

How Does Fully Automatic Pouch Packing Machine Cost?

The fully automatic pouch packing machine varied from the machine's features and package efficiency. If you want to get a detailed price, you can contact Soontrue.

What is Fully Automatic Pouch Packing Machine?

The fully automatic pouch packing machine is a versatile automated packaging equipment to help you expand your business. The fully automatic pouch packing machine can pack a wide range of regular and solid products, such as face masks, cakes, bread, biscuits, instant noodles, chocolates, daily necessities, medicines, hardware, or various tray-based items

What Are the Features of A Fully Automatic Pouch Packing Machine?

Revolutionize your packaging process with our state-of-the-art Fully Automatic Pouch Packing Machine. Engineered for precision, efficiency, and convenience, this cutting-edge equipment is the ultimate solution for businesses seeking to streamline their production and packaging operations. Here are some key features of a fully automatic pouch packing machine:

Precision Packaging: Our fully automatic pouch packing machine is designed to deliver precise and consistent results every time. Say goodbye to manual errors and variations in packaging quality.

High Speed: With its high-speed operation, this machine can significantly increase your production output, allowing you to meet growing demands with ease. It's the ideal choice for businesses aiming to scale up their operations.

Versatility: This versatile machine is compatible with a wide range of pouch sizes and materials. Whether you're packaging snacks, liquids, powders, or granules, it can handle a variety of products with ease.

User-Friendly Interface: The intuitive user interface makes it easy for operators to set up and control the machine. You can quickly adjust settings, monitor the packaging process, and maintain consistency in your products.

Robust Construction: Built to last, our pouch packing machine is constructed from high-quality materials, ensuring durability and reliability. It's a long-term investment that will serve your business well for years to come.

Low Maintenance: Designed with efficiency in mind, this machine requires minimal maintenance, reducing downtime and operational costs.

Sealing Perfection: The fully automatic pouch packing machine's sealing mechanism ensures airtight and tamper-proof packaging, preserving the quality and freshness of your products.

Safety Features: Safety is a top priority. The machine is equipped with advanced safety measures to protect both operators and products during the packaging process.

Precision Packaging: Our fully automatic pouch packing machine is designed to deliver precise and consistent results every time. Say goodbye to manual errors and variations in packaging quality.

High Speed: With its high-speed operation, this machine can significantly increase your production output, allowing you to meet growing demands with ease. It's the ideal choice for businesses aiming to scale up their operations.

Versatility: This versatile machine is compatible with a wide range of pouch sizes and materials. Whether you're packaging snacks, liquids, powders, or granules, it can handle a variety of products with ease.

User-Friendly Interface: The intuitive user interface makes it easy for operators to set up and control the machine. You can quickly adjust settings, monitor the packaging process, and maintain consistency in your products.

Robust Construction: Built to last, our pouch packing machine is constructed from high-quality materials, ensuring durability and reliability. It's a long-term investment that will serve your business well for years to come.

Low Maintenance: Designed with efficiency in mind, this machine requires minimal maintenance, reducing downtime and operational costs.

Sealing Perfection: The fully automatic pouch packing machine's sealing mechanism ensures airtight and tamper-proof packaging, preserving the quality and freshness of your products.

Safety Features: Safety is a top priority. The machine is equipped with advanced safety measures to protect both operators and products during the packaging process.

Fully Automatic Packing Machine

Introducing our state-of-the-art Fully Automatic Packing Machine – a revolutionary solution to streamline your packaging process with unmatched efficiency and precision. Designed to meet the demands of modern industries, this cutting-edge machine takes automation to the next level.

With its advanced technology, our Fully Automatic Packing Machine effortlessly handles the entire packaging workflow from start to finish. Say goodbye to manual labor and hello to increased productivity. This machine ensures consistent and accurate packaging, reducing errors and minimizing wastage.

Equipped with user-friendly controls, the Fully Automatic Packing Machine is easy to operate, allowing you to customize settings to suit your specific packaging requirements. Its high-speed capabilities make it ideal for large-scale production, ensuring that your products are packed swiftly without compromising on quality.

Invest in efficiency, precision, and speed with our Fully Automatic Packing Machine – the game-changer your business needs for seamless, hassle-free packaging. Upgrade your production process and experience the future of automated packaging technology today.

Increase your packaging efficiency and quality with the Fully Automatic Pouch Packing Machine. It's a game-changer for businesses looking to stay ahead in today's competitive market. Invest in the future of your packaging operations and experience the benefits of automation.

Don't miss out on this opportunity to enhance your packaging capabilities. Contact us today to learn more and request a quote. Upgrade to the fully automatic pouch packing machine and take your packaging process to the next level!

automatic wrapping machine With its advanced technology, our Fully Automatic Packing Machine effortlessly handles the entire packaging workflow from start to finish. Say goodbye to manual labor and hello to increased productivity. This machine ensures consistent and accurate packaging, reducing errors and minimizing wastage.

Equipped with user-friendly controls, the Fully Automatic Packing Machine is easy to operate, allowing you to customize settings to suit your specific packaging requirements. Its high-speed capabilities make it ideal for large-scale production, ensuring that your products are packed swiftly without compromising on quality.

Invest in efficiency, precision, and speed with our Fully Automatic Packing Machine – the game-changer your business needs for seamless, hassle-free packaging. Upgrade your production process and experience the future of automated packaging technology today.

Increase your packaging efficiency and quality with the Fully Automatic Pouch Packing Machine. It's a game-changer for businesses looking to stay ahead in today's competitive market. Invest in the future of your packaging operations and experience the benefits of automation.

Don't miss out on this opportunity to enhance your packaging capabilities. Contact us today to learn more and request a quote. Upgrade to the fully automatic pouch packing machine and take your packaging process to the next level!

Technical Parameters:

| Model | SZ502 |

| Center distance | 150mm |

| Bagging size range | L120-500mm Max. W220mm Max. H80mm |

| Packing speed | 30-120 bags/min. |

| Packing film width | Max. 500mm |

| Packing material | OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC etc. |

| General power | 6.6 kw |

| Power supply type | 1Ph. 220V 50Hz |

| Machine weight | 1200Kg |

| Machine dimensions | 4330 x 1110x 1650mm |

Last: There is no result

Related Products

Along with the market developing trends,Soontrue machines come into a servo age whom concentrated on researching and developing.