Horizontal packaging machine - SZ280J

Application:

Mainly used for packing various kinds of irregular,sticky or bulky products, such as egg roll, sausage,squid, bread, instant noodles, preserved fruit, jellycandy, toilet soap, pocket notebook, stick tape,medicine, and so on.

SW280J automated horizontal packaging machine

Introduction:

SW280J horizontal flow wrap machine is ideal for suppliers of products that must be packaged individually. Flow wrapping is a horizontal packaging process in which product enters the machinery and is wrapped in clear or printed film. The result is a tightly fitted flexible package with a horizontal back seal and end seal.

Application:

Automatic flow packing machine is a widely used packing machine. It Suitable for all kinds of product packaging. Including medical supplies, vegetables and meat, baked bread, snacks and candy, daily necessities, hardware accessories, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Horizontal Full Servo-Control Packaging Machine Features

Simple system structure

The system is composed of servo motors, servo drivers, and a touch screen. The servo driver integrates motion control logic without the need for an independent controller. All wiring uses connector assemblies, resulting in a compact design, easy maintenance, and competitive cost performance.

Simple operation

Equipped with an intelligent HMI control system, the machine allows easy parameter setting and adjustment, reducing commissioning time.

Wide bagging size range

Bag length can be set flexibly through color mark tracking or preset bag length modes, making changeovers faster and easier.

Shaftless driving technology

Adopts shaftless driving with no mechanical joints. Each shaft is independently controlled by a servo motor with a gear reducer for improved precision and stability.

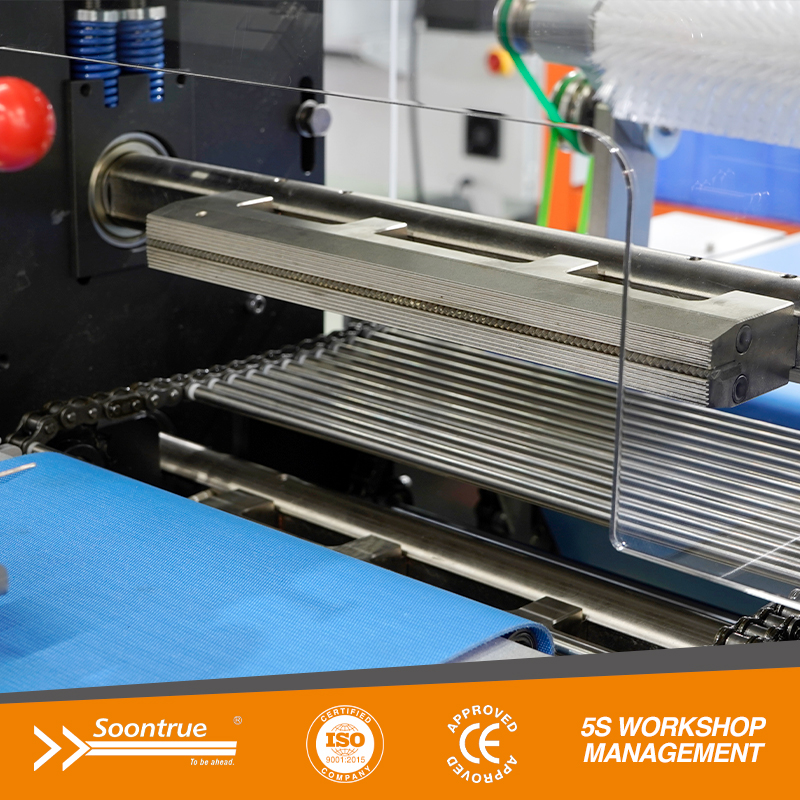

Auto-shift cutter

The cutter operates with variable shift. The speed curve is generated automatically, eliminating manual adjustment and replacing traditional mechanical cams.

High-speed performance

- Maximum line speed up to 50 m/min

- Maximum packing speed up to 200 bags/min (double jaws) with color mark tracking

High color mark tracking accuracy

Tracking accuracy reaches up to 0.1 mm, ensuring consistent seal positioning.

Packless function

Ensures every package contains a product, whether in-feed is continuous or intermittent, reducing film waste.

Cutless function

If a product is detected out of position, the cutter stops and restarts only after the product is discharged, preventing product damage.

Automatic film splicer

Automatically splices a new film roll without stopping the machine, saving labor and production time.

Cutter torque protection

The system monitors cutter resistance in real time. If resistance exceeds the preset torque value, the cutter stops and reverses automatically to protect both the product and the machine.

Customizable special functions

The machine can be modified according to customer requirements and equipped with multiple safety protection devices and various automatic feeding systems.

Machine Standard Features (SW280X)

- Sanitary machine design for easy cleaning

- Compact machine body with a small footprint

- Intelligent control system with servo motors

- Color mark tracking system

- Easy integration with Soontrue automatic feeding systems and other upstream or downstream equipment

Maintenance and Inspection

Daily or Per-Shift Maintenance

- Clean the machine after each packaging operation

- Turn off power and allow heating parts to cool before cleaning

- Do not spray water or steam directly on the machine

Clean key components:

- In-feed conveyor (compressed air or manual cleaning)

- Cutter surface (wire brush with silicone oil)

- Control panel and safety cover (soft cloth)

- Conductive rings of sealing tools (weekly or biweekly with power off)

Monthly Maintenance

- Lubricate bearings of end sealers

- Lubricate gears and chains (pulleys)

- Check and tighten chains, belts, screws, and nuts

Semi-Annual Inspection

- Inspect and replace worn belts

- Check rubber rollers affecting film feeding

- Adjust brake unit of film-carrying roller

- Inspect all wearing parts and electrical wiring

- Clean inverter, PLC, and circuit boards using compressed air

FAQ

Q1: What type of machine for food packaging do you have?

Answer: We recommend suitable models based on product characteristics, size, and placement type, such as top film loader, bottom film loader, rotary end sealing, box motion end sealing, and more. Different in-feed conveyors, including chain type, belt type, and feeding-on-film type, are also available.

Q2: I'm worried that I don't know how to operate your machine.

Answer: Do not worry. Our packaging machines are servo controlled, which greatly simplifies operation and commissioning. Most daily operations can be completed via start-stop buttons and the HMI. Instructional videos are available, and the HMI memory function allows easy reloading of saved settings.

Q3: If I buy your automatic packaging machine, what technical support can I get?

Answer: We provide 24-hour online technical support, as well as instructional videos for installation, commissioning, and maintenance. For customized automatic packing systems, on-site installation and commissioning services are available upon request (buyer bears the cost).

Q4: How do we build trust in the first business?

Answer: We believe trust is built through professional service and reliable products. We clearly explain solutions based on your needs and offer factory visits via video call. Factory acceptance tests can be completed through on-site inspection, test videos, or live video calls before shipment.

Q5: How can I find the custom packaging machine I need?

Answer: We will fully communicate with you about your product details, packaging scheme, and feeding method. With nearly 30 years of manufacturing experience, we can provide similar case references and request samples for testing if needed to determine the most suitable and cost-effective solution.

Technical Parameters:

| Model | SW280J | |||

| Center distance | 180mm | |||

| Bagging size range | L120-1000mm W70-200mm H60-150mm |

|||

| Packing speed | 5-30 bags/min. | |||

| Packing film width | 200-600mm | |||

| Packing material | OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC etc. | |||

| General power | 5.9 kw | |||

| Power supply type | 1Ph. 220V 50Hz | |||

| Machine weight | 775Kg | |||

| Machine dimensions | 4330 x 1130 x 1410mm | |||