Film roll Secondary Flow Wrapping Machine - SZ602

Application:

Mainly used for packing various regular and solid products such as multi-pcs face masks, cake, bread, biscuit, instant noodle, chocolate, daily necessities, medicine, hardware or any product in tray.

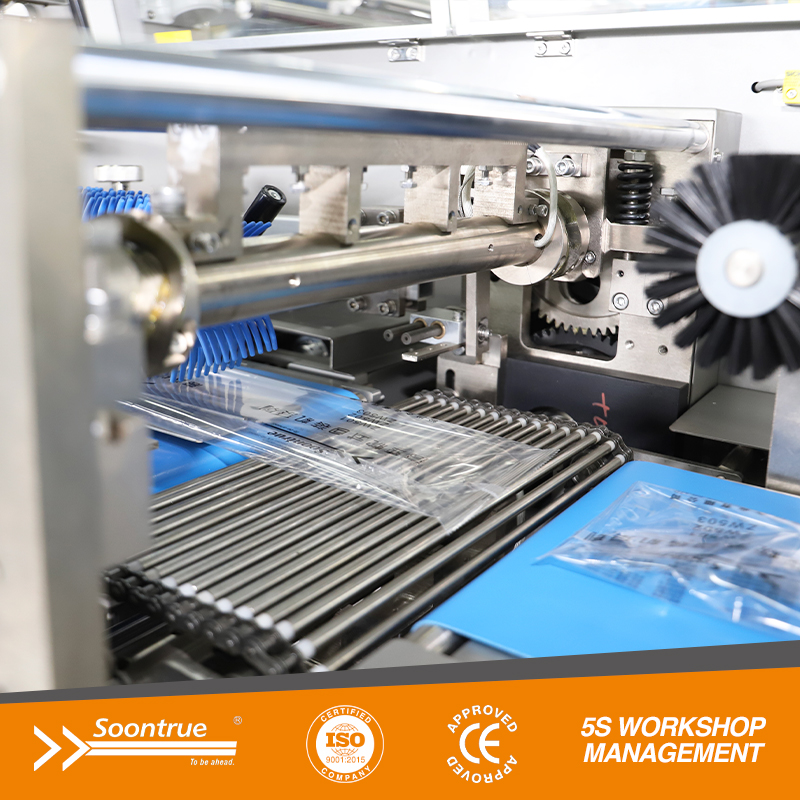

film roll flow packer Film roll Secondary Flow Wrapping Machine

Pillow Packaging Machine: Introduction

SZ602 horizontal flow wrap machine is ideal for suppliers of products that must be packaged individually. Flow wrapping is a horizontal packaging process in which product enters the machinery and is wrapped in clear or printed film. The result is a tightly fitted flexible package with a horizontal back seal and end seal.

Application:

Suitable for packing regular objects such as biscuits, pies, bread, instant noodles, drugs, daily appliances, industrials parts, paper boxes, plates, vegetable, fruit, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

SZ Series Full Servo-control Packaging Machine Features

- Reasonable machine configuration with streamlined appearance design, low noise, fewer troubles, and easy maintenance.

- Multi-axis full servo-control system ensures simple operation, stable function, high control accuracy, and low power dissipation.

- Color touch screen display allows convenient adjustment, self-diagnosis, and data storage. Product size changes can be carried out easily.

- High-accuracy and high-sensitivity color mark tracking system controls bag length precisely.

- Equipped with wrong bag position detection and material anti-cutting functions.

- Intelligent digital temperature controller enables accurate individual temperature control, suitable for various packing materials.

- Automatic stop function when no product is detected helps avoid film waste.

- Fully automatic material-feeding function reduces manpower requirements.

- Stopping position can be randomly adjusted for easy operation.

- Optional seal patterns available, including straight line, vertical line, or net line.

- All-purpose bag former can be randomly adjusted and easily operated.

- Various cutting types are available for selection.

- Date-printing position can be freely adjusted.

- Multiple safety protection devices are integrated into the whole machine.

- Strong extensibility: can be equipped with various automatic feeding devices.

SZ602 Machine Standard Features

- Sanitary machine design for easy cleaning

- Robust machine construction

- Stainless steel body frame

- High-precision color mark tracking

- Easy integration with Soontrue's full line of automatic feeding systems and other upstream or downstream equipment

Maintenance and Inspection

Daily or Every Shift Maintenance

- Clean the machine after each packaging operation.

- Turn off the power before cleaning to allow heating parts to cool down.

- Never spray water or steam directly onto the machine.

- Main components to be cleaned:

- Remove product chips accumulated on the conveying line using compressed air or other methods.

- Brush off film chips on the sealing surface using a wire brush with silicone oil.

- Clean the control panel, safety cover, and operating surface with a soft cloth.

- Conductive ring of mid sealing tool and end sealers: clean once every one or two weeks with the power off, using the back of sandpaper.

Monthly Maintenance

- Apply lubricating grease to the bearings of the end sealers.

- Apply lubricating grease to the gears and chains (pulleys) of the driving unit.

- Check chain and belt tightness of the driving unit and tighten if loosened.

- Check fastening screws and nuts of all parts and tighten if necessary.

Half-Year Inspection

- Check the wear condition of the driving unit belt and replace if worn.

- Inspect the rubber roller and replace if it affects film advancing.

- Properly adjust the brake unit of the film-carrying roller.

- Inspect all wearing parts and replace damaged components immediately.

- Check wiring connections on the electrical terminal plate and tighten if loose.

- Inspect inverter, programmable controller, and circuit boards; remove dust using compressed air.

FAQ

Q1: What type of machine for food packaging do you have?

Answer: We will recommend suitable models based on your product characteristics, size, and placement type, such as machines with top film loaders, bottom film loaders, rotary end sealing, or box motion end sealing. Different in-feed conveyors are also available to suit various feeding methods, including chain type, belt type, and feeding-on-film type.

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our packaging machines are servo controlled, which greatly simplifies operation and commissioning. Most daily operations are completed through a few start-stop buttons and the HMI. If product or package changes are required, we provide step-by-step instructional videos. The HMI also features a memory function for quick setting reload.

Q3: If I buy your automatic packaging machine, what technical support can I get?

Answer: Whether purchasing a customized packaging machine or a complete automatic packaging system, we provide 24-hour online technical support. We also offer instructional videos for installation, daily commissioning, and maintenance. For customized automatic packing systems, on-site installation and commissioning services can be provided upon request (buyer bears the cost).

Q4: How do we build trust in the first business?

Answer: We believe a win-win partnership is built on professional service and reliable products. Our team will thoroughly analyze your needs and clearly explain solutions. We can arrange factory visits via video call and conduct factory acceptance tests through video or live connections before shipment to ensure machine quality.

Q5: How can I find the custom packaging machine I need?

Answer: We will fully communicate regarding your product information, packaging scheme, and feeding method. With nearly 30 years of experience as a packaging machine factory, we can provide similar case videos for reference. If necessary, product samples and packaging films can be tested to identify the most suitable and cost-effective solution.

| Model | SZ601 | SZ602 | SZ601W | SZ602W | |

| Center distance | 150mm | 150mm | 120mm | 120mm | |

| Bagging size range | L120-600mm W70-220mm H20-80mm |

L120-600mm W70-200mm H20-80mm |

L120-600mm W70-200mm H5-80mm |

L120-600mm W70-200mm H20-80mm |

|

| Packing speed | 25-100 bags/min. | 25-100 bags/min | 20-80 bags/min | 25-80 bags/min | |

| Packing film width | Max. 600mm | Max.600mm | Max.600 | Max.600mm | |

| Packing material | OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC etc. | ||||

| General power | 8.0kw | 7.6kw | 9.0kw | 8.6kw | |

| Power supply type | 1Ph. 220V 50Hz | ||||

| Machine weight | 700kg | 700kg | 800kg | 800kg | |

| Machine dimensions | 5130x1430x1480mm | 4500x1180x1590mm | 5350x1230x1470mm | 4500x1070x1590mm | |