Full Servo Flow Wrapping Machine – SI-150

Application:

Mainly used for packing various regular and trayless product on edge. Such as biscuits, crackers, cookie, cake rust, dry bread, potato chips and so on.

The SI-150 Horizontal Flow Wrapping Machine is designed for suppliers who need to package products individually with precision and speed. Utilizing horizontal flow wrapping, products are automatically wrapped in clear or printed film, resulting in a tight-fitting, flexible package with horizontal back and end seals.

This machine is ideal for food, consumer goods, and industrial products requiring hygienic, reliable, and customizable packaging solutions.

Customizable options available – our R&D engineers can tailor the machine according to your product specifications.

Key Features

Full Servo-Control System

Simple system structure with servo motors, built-in servo driver, and touch screen HMI.

Compact design ensures easy maintenance and competitive pricing.

Easy Operation

Intelligent HMI allows simple parameter settings and quick adjustments.

Flexible Bag Size

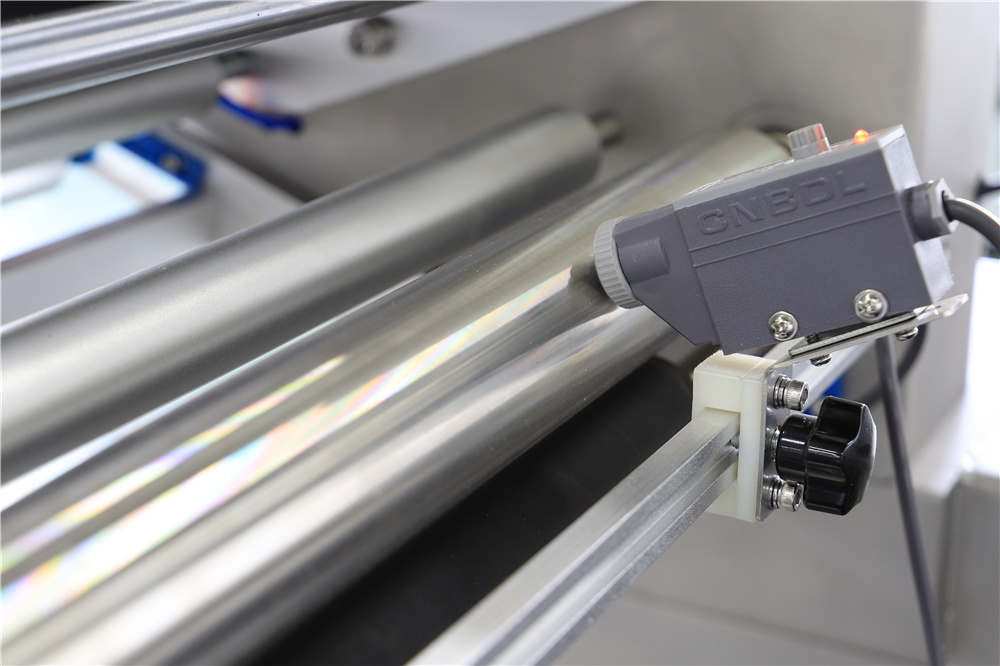

Wide bag length range, adjustable via color mark tracking or preset values.

Advanced Motion Control

Shaftless driving system with individual servo motors for each axis.

Auto-shift cutter generates speed curve automatically, eliminating mechanical cams.

High Speed & Accuracy

Maximum line speed up to 50m/min.

Maximum packing speed up to 200 bags/min (double jaws).

Color mark tracking accuracy up to 0.1mm.

Smart Functions

Packless Function: Prevents empty bags, reduces film waste.

Cutless Function: Stops cutter if product mispositioned, restarts automatically.

Film Splicer: Automatic film roll splicing without stopping.

Cutter Torque Protection: Stops cutter on hard product to prevent damage.

Customizable Special Functions

Multiple safety protection devices.

Compatible with various automatic feeding systems.

Standard Features

Sanitary design for easy cleaning.

Compact footprint for space efficiency.

Servo-driven intelligent control system.

Color mark tracking for precise bag placement.

Easily integrates with Soontrue's automatic feeding lines and other equipment.

Maintenance & Inspection

Daily / Shift Maintenance

Clean in-feed conveyor, cutter, control panel, and sealing tools.

Always power off before cleaning.

Avoid spraying water/steam directly.

Monthly Maintenance

Lubricate bearings, gears, and chains.

Check and tighten chains, belts, screws, and nuts.

Half-Year Inspection

Replace worn belts and rollers.

Adjust brake units of film rollers.

Inspect wiring, inverter, PLC, and circuit boards; remove dust with compressed air.

FAQ

Q1: What type of horizontal packaging machines do you provide?

A: We recommend models based on your product type and feeding method: top/bottom film loaders, rotary end sealing, box motion sealing, and chain/belt conveyors.

Q2: I'm worried about operating the machine.

A: Our servo-controlled system with HMI simplifies operation. Instructional videos and memory function in HMI make product changes easy.

Q3: What technical support do you offer?

A: 24/7 online support, installation and maintenance videos, and on-site commissioning for custom projects (buyer covers costs).

Q4: How do we build trust for first-time business?

A: Video factory tours, acceptance tests, and detailed case references ensure transparency and confidence before shipment.

Q5: How can I find a custom solution?

A: Share product samples, packaging films, and feeding requirements. With nearly 30 years of experience, we provide the most suitable and cost-effective solution.

Why Choose Soontrue?

Established in 1993, Soontrue is a leading horizontal flow wrapping machine manufacturer in China. With high-quality machines, professional service, and global reputation, we deliver innovative, reliable, and efficient packaging solutions trusted worldwide.

| Model | SI-150 |

| Bagging size range | L130-400mm W30-140mm H35-70mm |

| Packing speed | 30-100bags/min |

| Packing film width | 80-400mm |

| Packing material | OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC etc. |

| General power | 7.35 kw |

| Power supply type | 1Ph. 220V 50Hz |

| Machine weight | 670Kg |

| Machine dimensions | 4856 x 969 x 1626mm |